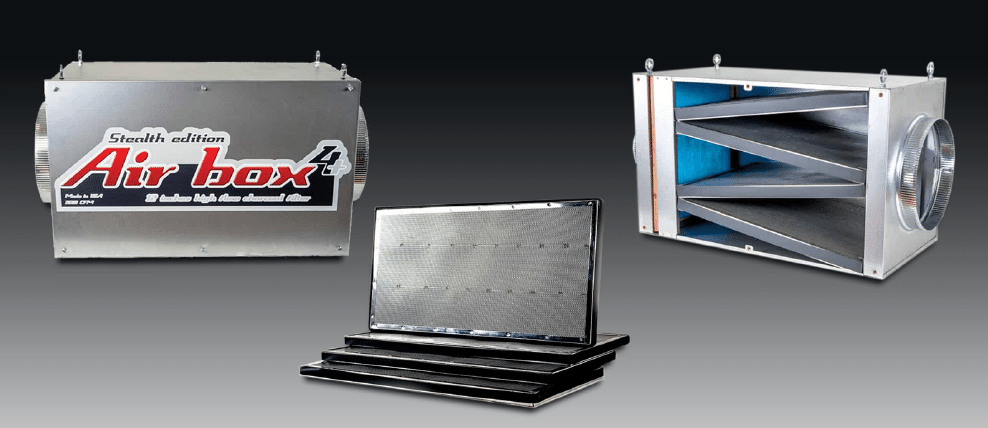

The First Line of Defense: Why the Air Box Pre-Filter Matters

In high-demand environments—commercial facilities, industrial operations, hospitality venues, cigar lounges, and specialty spaces—air filtration systems are only as strong as their first stage.

In both Air Box and Air Box Junior units, the pre-filter serves a critical engineering function:

The Air Box pre-filter is the first line of defense — capturing larger particles before they reach your carbon or HEPA filters, keeping your system cleaner and running longer.

For operators focused on performance, uptime, and cost efficiency, this first stage is not optional. It is foundational.

Engineering Purpose of the Pre-Filter

From a system design perspective, staged filtration is essential to optimize airflow, pressure drop, and media longevity.

The pre-filter is designed to:

- Capture larger airborne particulate (dust, lint, fibers, hair, pollen, debris)

- Reduce contaminant loading on downstream filters

- Maintain stable airflow performance

- Minimize premature carbon saturation

- Protect HEPA media from excessive particulate burden

By intercepting coarse particulate early, the pre-filter significantly reduces resistance buildup within the system.

Performance Benefits for Commercial & Industrial Users

1. Extended Carbon Filter Life

Activated carbon is highly effective for odor and VOC removal—but particulate loading reduces its efficiency. When dust coats carbon granules, adsorption performance declines.

By capturing larger debris upstream, the pre-filter:

- Preserves carbon pore structure

- Delays odor breakthrough

- Reduces total cost of ownership

This is especially critical in:

- Cigar lounges and tobacco environments

- Food production facilities

- Manufacturing spaces

- Indoor growing operations

- Hospitality venues with high occupancy

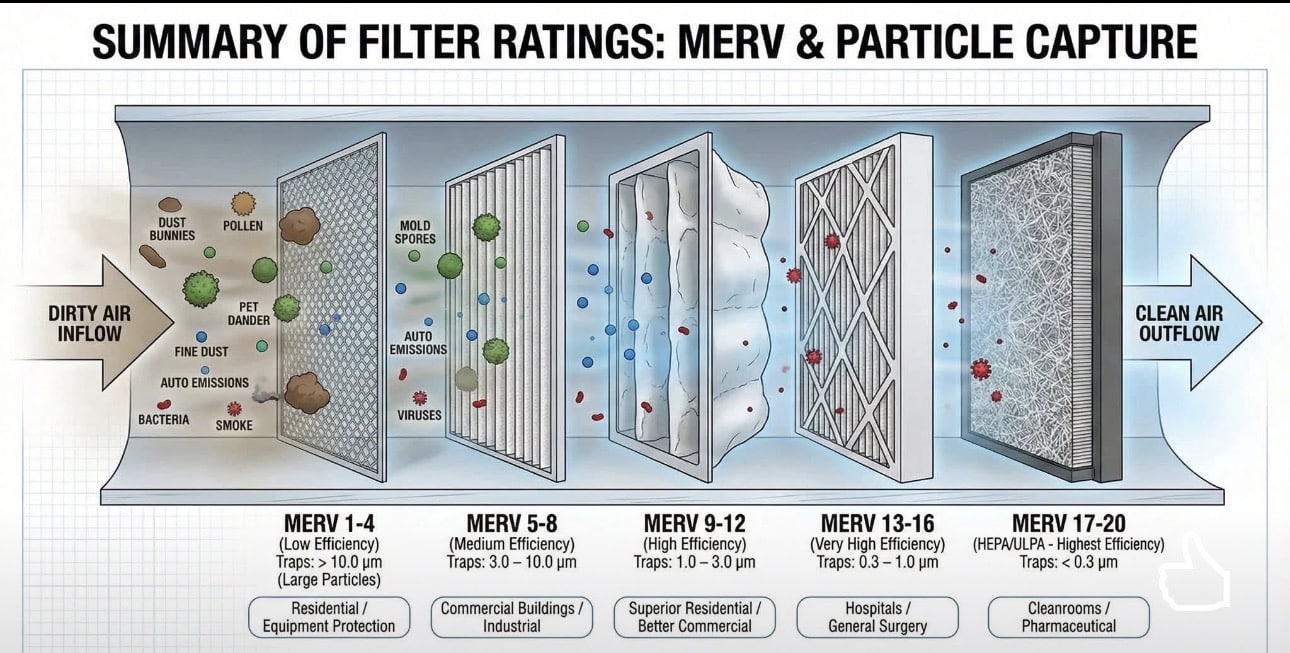

2. HEPA Protection and Efficiency (Air Box Junior Add-On)

For environments using Air Box Junior HEPA filtration, the pre-filter prevents coarse particulate from prematurely clogging the HEPA media.

Without pre-filtration:

- HEPA filters experience faster pressure drop

- Fan energy consumption increases

- Air exchanges per hour decline

- Replacement intervals shorten

With pre-filtration:

- HEPA maintains rated efficiency (99.97% @ 0.3 microns)

- Airflow remains stable

- System performance stays within design specifications

3. Maintained Airflow & Reduced Static Pressure

From an engineering standpoint, airflow consistency is critical.

As particulate accumulates inside deeper filtration stages:

- Static pressure rises

- Fan efficiency decreases

- Noise levels can increase

- System lifespan shortens

The pre-filter reduces downstream loading, helping maintain optimal airflow through:

- Carbon filters

- HEPA modules

- RUCK inline fan systems

The result: predictable, stable system operation.

Designed for Real-World Applications

Air Box systems are used across:

- Commercial environments (restaurants, cigar lounges, hospitality spaces)

- Industrial facilities (production areas, fabrication shops)

- Residential applications

- Indoor growing operations

In these spaces, airborne particulate varies dramatically depending on occupancy, process activity, and layout. The pre-filter acts as a protective buffer against unpredictable environmental loads.

Easily Replaceable = Operational Efficiency

Maintenance simplicity is a core design principle.

Air Box pre-filters are:

- Easily accessible

- Simple to replace

- Cost-effective

- Designed for routine service intervals

Replacing a pre-filter on schedule:

- Extends carbon and HEPA life

- Reduces downtime

- Protects system performance

- Lowers long-term filtration costs

For hospitality and commercial operators, this translates directly into operational savings and improved air quality consistency.

Filter Stage Overview: How the System Works

Air Box systems utilize staged filtration for maximum performance.

Stage 1 – Pre-Filter

Captures larger particulate (dust, lint, debris, hair, pollen).

Protects downstream filters and stabilizes airflow.

Stage 2 – Activated Carbon Filter

Adsorbs smoke, odors, VOCs, and gaseous contaminants.

Ideal for tobacco smoke, blue haze, chemical odors, and hospitality environments.

Stage 3 – HEPA Filtration (Air Box Junior Optional Add-On)

Captures ultra-fine particulate down to 0.3 microns at 99.97% efficiency.

Provides high-level air purification where fine smoke or particulate control is required.

Air Movement – RUCK Inline Fan

Drives consistent airflow through a straight-thru filtration path, ensuring efficient scrubbing and circulation.

Strategic Value for Hospitality & High-Occupancy Spaces

In cigar lounges, bars, and social venues, air quality is directly tied to:

- Guest comfort

- Staff health

- Brand reputation

- Regulatory compliance

The pre-filter ensures the entire filtration system operates at peak efficiency—quietly and reliably—without creating excessive maintenance demands.

The Bottom Line

In engineered air systems, longevity and performance begin at the first stage.

The Air Box pre-filter is not just a dust screen — it is the foundation of system efficiency.

By capturing larger particulate before it reaches carbon or HEPA filters, it:

- Extends filter life

- Maintains airflow performance

- Reduces energy strain

- Lowers maintenance costs

- Preserves air quality standards

For commercial, industrial, and hospitality operators who depend on clean, consistent air, the first line of defense makes all the difference.

Protect your filters. Protect your airflow. Protect your air quality.

Air Box — engineered for performance.

For residential, commercial and industrial applications. Order Air Box filters and Ruck inline fans direct from the manufacturer at: www.airboxfilter.com